A True Craft Chiller Company – Building Brewery Glycol Chillers – By Hand – One Unit At A Time

Brewery chillers used in the fermentation and pull down (cold crashing) process typically circulate 28°F degree glycol for 33°F degree beer. Brewery chillers run at temperatures below 32°F (freezing) and thus require propylene glycol (food grade HVAC type anti-freeze)

SIZING A BREWERY GLYCOL CHILLER

Follow this “Brewery Glycol Chiller Sizing” Link for assistance, formulas and helpful information for sizing your chiller.

Package Brewery Chiller with tank and pump all in one package

-

- Popular with brewers because of its all-in-one design

- Offers a simplified installation

- Set the chiller, run wires, connect the fluid supply and return lines, fill with water/glycol and start-up

Modular Brewery Chillers with tank and pump(s) ship separate. Ideal for growing breweries

-

- Allows a brewery with rapid growth plans to add chiller modules as the brewery grows, without replacing the chiller

- Matching present needs without over sizing – saves on budget and electricity

- When the roof can’t support the weight of the glycol tank and pump(s)

- When chiller is located a long distance from brew tanks

- Can be added to an existing system as a booster chiller

- Our sales engineers can help select components that work best for each brewery

Split Brewery Chillers keep the hot condenser air outdoors and all fluid components indoors. The indoor and outdoor units are connected with refrigeration line sets

- Multiple circuits are available in single phase power for sizes above 5 tons when 3 phase power not available

American Brewery Chillers are engineered with premium refrigeration components, similar to the critical systems required to run supermarket refrigerators and freezers. We use Copeland Scroll Compressors (in most sizes) which are superior to hermetic compressors (used by many competitors) in reliability and efficiency, most of which come with a 5 year warranty.

Each American Chiller ships with a chiller remote control panel for indoor installation so the brew master can easily control the chiller.

SIZING A BREWERY GLYCOL CHILLER

Follow this “Brewery Glycol Chiller Sizing” Link for assistance, formulas and helpful information for “sizing your chiller”.

Standard Features

- Heavy duty welded, steel frame with powder coat finish and laminated brushed aluminum cabinet

- U.L. Listed, and EPA Compliant, eco-friendly R404a refrigeration condensing unit (“green” refrigerants are available)

- Single refrigeration circuit with Copeland scroll compressor(s) with crankcase heater(s)

- Refrigerant receiver and suction side accumulator to eliminate refrigerant slugging in compressor

- Air cooled, horizontal discharge, oversized condensers with flooded head pressure controls for low ambient operation to -20F˚

- Weather proof electrical panel with single point power connection

- 24 vac control circuit with component sequenced terminal strip for easy troubleshooting

- Remote control panel for indoor installation provides lighted on/off switches and digital thermostat

- UL stainless steel brazed plate evaporator insulated against condensation with 3/4″ closed cell insulation

- Auto reset low pressure safety; manual reset high pressure safety

- Externally equalized thermal expansion valve, liquid line filter drier, and sight glass

- Low water flow compressor interlock safety locks out compressors in low flow condition

- Non-ferrous water lines with FPT connections insulated with 3/4” closed cell insulation

- High density, polyethylene reservoir insulated with closed cell insulation

- High head centrifugal process pump rated at 40 psi at 2.5 GPM/ton

- Internal bypass valve for temperature stability and to prevent pump dead heading

- Systems leak checked, pressure tested, run tested under load and shipped operation ready

- Brass wye strainer included (ships loose)

- Warranty: one (1) year limited parts, five (5) years limited compressor warranty

- Ships fully crated to minimize damage risk during shipping

Available Options

- Condenser coil coating for corrosion protection in salt air environments

- Dual, scroll compressor sets

- Dual refrigeration circuits

- Redundant chiller options

- EC fan motors

- Cabinet mounted fluid pressure and temperature gauges and refrigeration pressure gauge

- Inhibited propylene glycol concentrate in 55 gallon drums or 5 gallon carboys

- Magnum microprocessor controller for building automation control & full chiller analytics

- Dual pumps with lead/lag control

- Castors for portability (sizes 1 HP to 5 HP)

- R448, R407c, R404a, R410a refrigerant

- Custom options and configurations available

Package Chiller Specification Sheets

Brewery Glycol Chillers PDF Spec Sheet Downloads

Single Refrigeration Circuits

(C/F for dual circuit chiller data)

| Size | Model | |

| 1.0 HP | CAVCS010_BCK | 1 & 3 phase |

| 2.0 HP | CAVCS020_BCK | 1 & 3 phase |

| 2.5 HP | CAVCS025_BCK | 1 & 3 phase |

| 3.0 HP | CAVCS030_BCK | 1 & 3 phase |

| 4.0 HP | CAVCS040_BCK | 1 & 3 phase |

| 5.0 HP | CAVCS050_BCK | 1 & 3 phase |

| 7.6 HP | CAVCS076_BCK | 3 phase |

| 8.5 HP | CAVCS085_BCK | 3 phase |

| 11 HP | CAVCS110_BCK | 3 phase |

| 15 HP | CAVCS150_BCK | 3 phase |

| 20 HP | CAVCS200_BCK | 3 phase |

| 24 HP | CAVCS240_BCK | 3 phase |

| 30 HP | Consult Factory | 3 phase |

| 40 HP | Consult Factory | 3 phase |

Modular Chiller Specification Sheets

Brewery Chillers PDF Spec Sheet Downloads

Single Refrigeration Circuits

(C/F for dual circuit chiller data)

| Size | Model | Electrical |

| 1.0 HP | CAVSS010_BCK | 1 & 3 phase |

| 1.5 HP | CAVSS015_BCK | 1 & 3 phase |

| 2.0 HP | CAVSS020_BCK | 1 & 3 phase |

| 2.5 HP | CAVSS025_BCK | 1 & 3 phase |

| 3.0 HP | CAVSS030_BCK | 1 & 3 phase |

| 4.0 HP | CAVSS040_BCK | 1 & 3 phase |

| 5.0 HP | CAVSS050_BCK | 1 & 3 phase |

| 6.0 HP | CAVSS060_BCK | 3 phase |

| 7.6 HP | CAVSS076_BCK | 3 phase |

| 8.5 HP | CAVSS085_BCK | 3 phase |

| 11 HP | CAVSS110_BCK | 3 phase |

| 15 HP | CAVSS150_BCK | 3 phase |

| 20 HP | CAVSS200_BCK | 3 phase |

| 24 HP | CAVSS200_BCK | 3 phase |

| 30 HP | Consult Factory | 3 phase |

Installation Examples

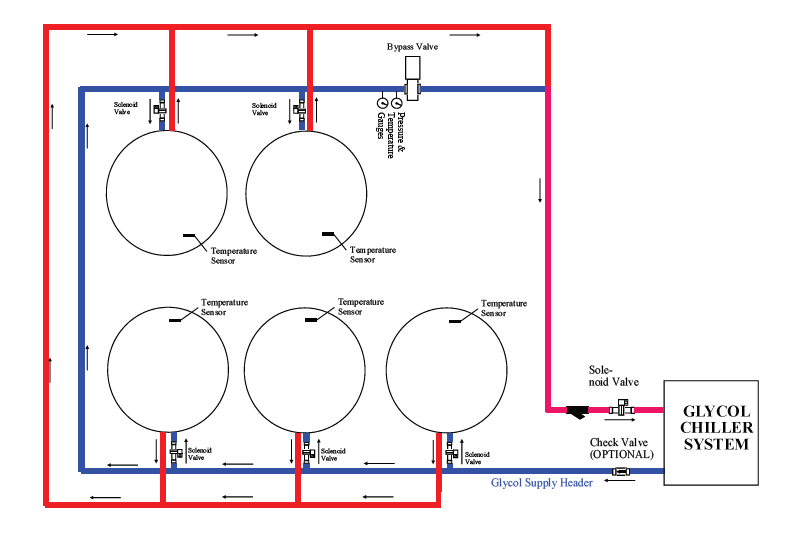

How To Pipe a Brewery Chiller and Fermentation Tanks

Using the last in – first out piping method allows the brewery tanks to equalize. The flow in the first tank (closest to the chiller) will be the same as the flow to the last tank (farthest away from the chiller). The result is equal cooling in all of the tanks.

What Happens When You Don’t Pipe First in – Last out?

Using a simple piping method of first tank in – first tank out causes the opposite to happen. The first tank or tanks in line get most of the flow (and cooling). The last tank or tanks get the least amount of flow or cooling. The result will often be a bad batch or bad batches of beer on the tanks farthest away from the chiller.

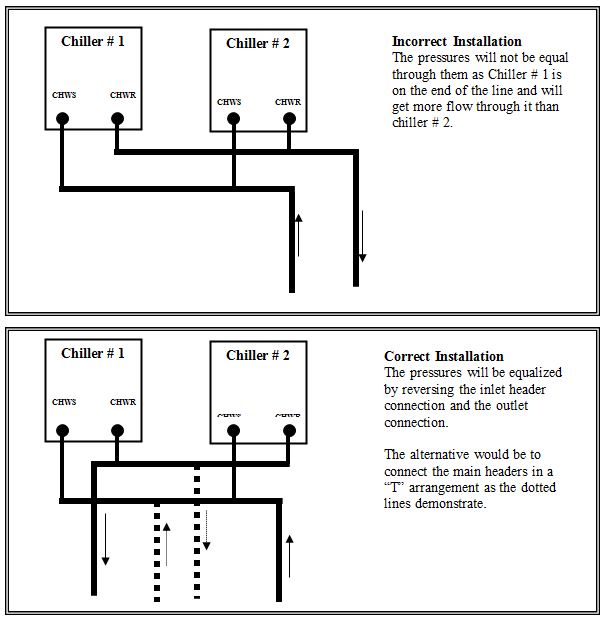

How To Pipe Multiple Modular Chillers (or a Booster Chiller)

Two or more modular chillers may be installed in a parallel piping system to provide more capacity of a single chiller or redundancy and multi-staging of compressors. The thermostats can be set a few degrees apart. If the lead chiller cannot maintain the fluid temperature, the second or lag chiller will stage on upon temperature rise and a third, etc. The diagram below illustrates the concept of parallel piping of the chillers on a common header system. The main header must be sized for the total flow rate and good practices dictates a maximum flow rate of 7 Ft/sec. When adding a chiller to an existing manifold system, also consider the ability of the pump to provide enough total flow and pressure to satisfy the process and the continuous flow through the chillers.

Installing A Bypass Loop

A properly placed and sized bypass is vital to the operation of every brewery cooling system

- To provide a continuously circulating water flow through the chiller coil, tank and piping system. This is necessary to maintain the reservoir at the cold temperature setting. The system should be balanced so that the flow through the bypass loop while maintaining sufficient flow to the process.

- To establish the minimum operating pressure of the cooling glycol supply to the brew tanks. This is a result of setting the continuous flow at maximum. This also establishes a higher pressure supply to the tanks and a lower pressure return to the chiller for good circulation through the tank jackets. The differential pressure between the supply and return is determined based on the maximum tank jacket pressure. Too much pressure and the tank jackets may be damaged. Too little pressure and there may not be enough pressure to push the flow through the tank jackets.

- To allow the chiller refrigeration to cycle on and off freely, and independently of external demands for flow and temperature and to minimize temperature swings in the chiller.

Where To Put The Bypass:

The bypass valve is best located at the end of the line, after the brewery fermentation and brite tanks and two stage wort heat exchanger (if equipped). If the bypass is installed before the tanks, the flow will be lower to the tanks when the tank solenoid valves are open. In a brewery, you want as much flow to the tank jackets as possible to keep the temperature fluctuation at a minimum. Lower flow results in a higher temperature difference between the supply and return and if too low, may result in inadequate heat transfer within the jacket. In simple terms, the glycol could warm up to tank temperature before flowing through the entire jacket and not providing enough cooling to pull down your tank(s).

Starving the Chiller:

Without a bypass or if the bypass is set too low (not allowing enough flow through the bypass), the brewery tanks and heat exchanger will get more pressure and flow.. But what happens to the chiller (and pump) if all of your solenoid valves are closed? The chiller will starve for flow causing the water temperature to be very cold coming out of the chiller but at a reduced flow that will cause the loop temperature to swing wildly between cold and hot (return fluid)! The purpose of the flowing loop has been defeated and the chiller can not maintain the reservoir and loop temperature at an even temperature. Worse yet, you may deadhead the pump and cause the pump motor to fail. Also, a lack of flow through the chiller will cause the chiller to shut down on the low flow safety resulting in a warm, glycol buffer tank (in the chiller) which will allow your glycol temperatures to fluctuate and not maintain a constant temperature of your beer.

Bypass Line Size:

The piping connections on the chiller are the correct size for the supply and return header lines based on sound engineering principles of flow, pressure drops, and fluid velocity. Reducing the line size from the recommended causes higher velocities, higher pressure drops, reduced supply pressure to the process, and fluctuations in the supply temperature.

What Type of Glycol Should be Used in a Brewery?

Glycol is a type of anti-freeze used in HVAC systems. Breweries require anti-freeze to keep the chiller and pipes from freezing when temperatures in the heat exchanger or around the chiller and/or piping reach temperatures near freezing. Glycol is required even when fluid temperatures are in the 50’s because the refrigerant in the chiller evaporator (heat exchanger) will reach freezing temeratures.

What Type of Glycol Should be Used in a Brewery? Breweries should use a food grade glycol with inhibitors to keep bacteria growth in check. American Chillers recommends USP Certified Inhibited Propylene Glycol. The food grade glycol will help to keep your customers from getting sick if there is a leak or contamination in your brew tank or process.

NEVER USE AUTOMOTIVE OR RV ANTI-FREEZE

Automotive anti-freeze contains lead. Lead is deadly if consumed by humans. It may also be deadly to your chiller as it is formulated for use with aluminum. RV anti-freeze may contain propylene glycol and be deemed food safe BUT it is not formulated for the constant heating and cooling and pumping of a brewery. It will break down and will most likely foul (clog) your chiller heat exchanger. It may also lose its effectiveness as it breaks down and may cause frozen and damaged pipes. The use of either RV or Automotive anti-freeze will also void your chiller warranty.

How Much Glycol Should be Used in a Brewery?

Breweries need to determine their glycol requirements based on twenty degrees Fahrenheit cooler than their glycol temperature (chiller set point) or based on their coldest possible winter ambient conditions, whichever is colder.

For example, if a brewery is located in Miami, Florida and they run their chiller at 28F degrees, they will mix their propylene glycol concentration based on 8F degrees. For a brewery in Ohio, they may base their glycol mixture on -5F degrees if that is their coldest winter ambient temperature.

Is Extra Glycol Better for my Brewery System?

You definitely want to make sure you are covered for the worst possible temperature scenario, but the more glycol you use, the less efficient the heat exchange in your chiller and the less efficient the heat exchange in your brewery jackets and 2-stage wort heat exchanger. Too much glycol may also be bad for your pump or make the solution too thick for your pump. Many breweries are now using low pressure tank jackets to save money. If you are located in an extremely cold environment, you may want to purchase higher pressure brew tanks (30 psi instead of 15 psi rated) or split your chiller, which keeps your fluid indoors and the heat exchanger outdoors.

Questions about what glycol concentration and/or type to purchase? Contact and American Chillers sales engineer for assistance.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Warranty

To Make A Warranty Claim:

Warranty policies may vary by customer, equipment and/or job. Refer to your sales documents and chiller manuals for details specific to your chiller.

To make a warranty claim, please call American Chillers Customer Service (803-822-3860) between the hours of 8:30 – 5pm eastern time, Monday – Friday or via email to csr@amchiller.com. All parts returned for credit must be pre-authorized. Once authorized, American Chillers will issue an Return Materials Authorization (RMA) number. Please include the RMA number on the outside of the package and also on the inside. Please take care in securely packaging the return parts to void shipping damage.

Maybe you might be interested

Texas Brewery Expansion

Many thanks to Mark Henry at Galveston Bay Brewery for the purchase of a new American Chillers 12 HP racked, Modular Brewery Glycol Chiller. American Chillers is thrilled to assist in the making of quality craft beers including Sunny Day, Bull Shark and Ghost Ship. This Brewery has a very interesting history dating back to […]

Southern California Has a New Brewery!

Many thanks to Andrew, Jeff and Kip at Los Angeles Ale Works for their new Brewery in Hawthorne, California. They chose an American Chiller 10 HP, dual refrigeration circuits, rack mounted modular chiller with a stand alone tank pump skid. Make sure to pay them a visit when in the area and select a beer […]

12 West Brewing – Arizona

Congratulation to Bryan McCormick and Noel Garcia for their brewery expansion which included an American Brewery Chiller, dual refrigeration circuit, 6 HP glycol chiller. Check out their craft beer offerings and brewery locations at www.12westbrewing.com.