For commercial and light industrial applications with fluid temperatures above 40°F

D-Series Commercial Chillers

For dry cleaning, some medical applications, plastics, metal finishing, industrial, test chambers, ice cream and yogurt machines, frozen daiquiri machine cooing, lab, residential and specialty air-conditioning.

Description: Commercial & Light Industrial usage for applications that require fluid temperatures between 40°F and 75°F.

1.5 to 20 Nominal tons.

*Other options available upon request. Contact factory for pricing and details.

| RATED TONS | MODEL | DIMENSIONS | LEAVING Water (°F ) |

80°F Ambient | 90°F Ambient | 95°F Ambient | 100°F Ambient | ||||||

| ( 110f ct ) | ( 120f ct ct) | ( 125f ct) | ( 130f ct) | ||||||||||

| Length | Width | Height | Btu/H | KW | Btu/H | KW | Btu/H | KW | Btu/H | KW | |||

| 1.5 | CAVP015S CAVM015S | 40 | 13.300 | 3,90 | 12.200 | 3,58 | 11.500 | 3,37 | 11.100 | 3,25 | |||

| 33 | 28 | 60 | 45 | 14.900 | 4,37 | 13.700 | 4,02 | 13.150 | 3,85 | 12.500 | 3,66 | ||

| 33 | 28 | 40 | 50 | 16.500 | 4,84 | 15.200 | 4,45 | 14.550 | 4,26 | 13.900 | 4,07 | ||

| 55 | 18.200 | 5,33 | 16.900 | 4,95 | 16.200 | 4,75 | 15.500 | 4,54 | |||||

| 60 | 20.100 | 5,89 | 18.700 | 5,48 | 17.950 | 5,26 | 17.200 | 5,04 | |||||

| 2 | CAVP020S CAVM020S | 40 | 18.300 | 5,36 | 16.800 | 4,92 | 16.000 | 4,69 | 15.200 | 4,45 | |||

| 33 | 28 | 60 | 45 | 20.400 | 5,98 | 18.850 | 5,52 | 18.200 | 5,33 | 17.100 | 5,01 | ||

| 33 | 28 | 40 | 50 | 22.500 | 6,59 | 20.900 | 6,13 | 20.000 | 5,86 | 19.100 | 5,60 | ||

| 55 | 24.800 | 7,27 | 23.100 | 6,77 | 22.200 | 6,51 | 21.300 | 6,24 | |||||

| 60 | 27.300 | 8,00 | 25.500 | 7,47 | 24.550 | 7,19 | 23.600 | 6,92 | |||||

| 3 | CAVP030S CAVM030S | 40 | 26.500 | 7,77 | 24.400 | 7,15 | 23.250 | 6,81 | 22.100 | 6,48 | |||

| 48 | 35 | 50 | 45 | 29.700 | 8,70 | 27.750 | 8,13 | 26.500 | 7,77 | 25.000 | 7,33 | ||

| 48 | 35 | 40 | 50 | 32.900 | 9,64 | 30.500 | 8,94 | 27.900 | 8,18 | 28.000 | 8,21 | ||

| 55 | 36.400 | 10,67 | 33.900 | 9,94 | 32.500 | 9,52 | 31.200 | 9,14 | |||||

| 60 | 40.100 | 11,75 | 37.400 | 10,96 | 36.100 | 10,58 | 34.800 | 10,20 | |||||

| 4 | CAVP040S CAVM040S | 40 | 35.700 | 10,46 | 32.900 | 9,64 | 31.400 | 9,20 | 29.900 | 8,76 | |||

| 48 | 35 | 58 | 45 | 40.000 | 11,72 | 37.100 | 10,87 | 35.400 | 10,37 | 33.800 | 9,91 | ||

| 48 | 35 | 40 | 50 | 44.300 | 12,98 | 41.100 | 12,05 | 39.400 | 11,55 | 37.700 | 11,05 | ||

| 55 | 49.000 | 14,36 | 45.500 | 13,33 | 43.700 | 12,81 | 41.900 | 12,28 | |||||

| 60 | 54.000 | 15,83 | 50.300 | 14,74 | 48.300 | 14,16 | 46.400 | 13,60 | |||||

| 5 | CAVP050S CAVM050S | 40 | 44.700 | 13,10 | 41.700 | 12,22 | 40.050 | 11,74 | 38.400 | 11,25 | |||

| 48 | 35 | 58 | 45 | 54.000 | 15,83 | 46.900 | 13,75 | 44.750 | 13,11 | 42.600 | 12,48 | ||

| 35 | 35 | 56 | 50 | 54.000 | 15,83 | 50.500 | 14,80 | 48.600 | 14,24 | 46.800 | 13,72 | ||

| 55 | 59.500 | 17,44 | 55.500 | 16,27 | 53.500 | 15,68 | 51.500 | 15,09 | |||||

| 60 | 65.000 | 19,05 | 61.000 | 17,88 | 59.400 | 17,41 | 56.500 | 16,56 | |||||

| 6.5 | CAVP065S CAVM065S | 40 | 58.000 | 17,00 | 54.000 | 15,83 | 48.700 | 14,27 | 44.300 | 12,98 | |||

| 48 | 35 | 58 | 45 | 64.500 | 18,90 | 58.100 | 17,03 | 54.800 | 16,06 | 49.800 | 14,59 | ||

| 43 | 31 | 33 | 50 | 71.000 | 20,81 | 66.000 | 19,34 | 61.000 | 17,88 | 55.500 | 16,27 | ||

| 55 | 78.000 | 22,86 | 73.000 | 21,39 | 66.500 | 19,49 | 61.500 | 18,02 | |||||

| 60 | 85.500 | 25,06 | 80.000 | 23,45 | 74.000 | 21,69 | 68.500 | 20,08 | |||||

| 7.5 | CAVP075S CAVM075S | 40 | 72.000 | 21,10 | 67.000 | 19,64 | 64.500 | 18,90 | 62.000 | 18,17 | |||

| 48 | 35 | 58 | 45 | 77.500 | 22,71 | 73.750 | 21,61 | 70.900 | 20,78 | 68.750 | 20,15 | ||

| 43 | 31 | 33 | 50 | 87.000 | 25,50 | 81.500 | 23,89 | 78.500 | 23,01 | 75.500 | 22,13 | ||

| 55 | 95.500 | 27,99 | 89.500 | 26,23 | 86.300 | 25,29 | 83.000 | 24,32 | |||||

| 60 | 104.000 | 30,48 | 98.000 | 28,72 | 95.500 | 27,99 | 91.000 | 26,67 | |||||

| 10 | CAVP100S CAVM100S | 40 | 90.000 | 26,38 | 84.000 | 24,62 | 81.700 | 23,94 | 77.500 | 22,71 | |||

| 66 | 44 | 74 | 45 | 99.500 | 29,16 | 93.500 | 27,40 | 90.700 | 26,58 | 86.700 | 25,41 | ||

| 61 | 39 | 45 | 50 | 109.000 | 31,94 | 103.000 | 30,19 | 99.000 | 29,01 | 95.000 | 27,84 | ||

| 55 | 120.000 | 35,17 | 113.000 | 33,12 | 109.000 | 31,94 | 105.000 | 30,77 | |||||

| 60 | 132.000 | 38,69 | 124.000 | 36,34 | 119.500 | 35,02 | 115.000 | 33,70 | |||||

| 12.5 | CAVP125S CAVM125S | 40 | 115.000 | 33,70 | 106,000 | 31,07 | 101.500 | 29,75 | 97.000 | 28,43 | |||

| 78 | 44 | 74 | 45 | 137.500 | 40,30 | 118.000 | 34,58 | 112.700 | 33,03 | 108.500 | 31,80 | ||

| 73 | 39 | 45 | 50 | 140.000 | 41,03 | 130.000 | 125.000 | 36,63 | 120.000 | 35,17 | |||

| 55 | 124.900 | 36,60 | 144.000 | 42,20 | 138.000 | 40,44 | 132.000 | 38,69 | |||||

| 60 | 169.000 | 49,53 | 158.000 | 46,31 | 152.500 | 44,69 | 147.000 | 43,08 | |||||

| 15 | CAVP150S CAVM150S | 40 | 142.000 | 41,62 | 132.000 | 38,69 | 127.000 | 37,22 | 122.000 | 35,75 | |||

| 93 | 44 | 74 | 45 | 157.000 | 46,01 | 146.000 | 42,79 | 140.000 | 41,03 | 135.500 | 39,71 | ||

| 88 | 39 | 45 | 50 | 172.000 | 50,41 | 160.000 | 46,89 | 154.500 | 45,28 | 149.000 | 43,67 | ||

| 55 | 188.000 | 55,10 | 176.000 | 51,58 | 171.000 | 50,12 | 164.000 | 48,06 | |||||

| 60 | 205.000 | 60,08 | 193.000 | 56,56 | 186.500 | 54,66 | 180.000 | 52,75 | |||||

| 20 | CAVP200S CAVM200S | 30 | 170.500 | 49,97 | 155.500 | 45,57 | 147.100 | 43,11 | 140.600 | 41,21 | |||

| 93 | 44 | 74 | 40 | 213.000 | 62,42 | 196.000 | 57,44 | 187.000 | 54,80 | 178.000 | 52,17 | ||

| 88 | 39 | 45 | 50 | 261.100 | 76,52 | 242.000 | 70,92 | 232.500 | 68,14 | 222.900 | 65,33 | ||

| 55 | 285.600 | 83,70 | 268.100 | 78,57 | 257.400 | 75,44 | 246.700 | 72,30 | |||||

| 60 | 314.700 | 92,23 | 294.000 | 86,16 | 283.600 | 83,11 | 271.600 | 79,60 | |||||

Note – American Chillers & Cooling Tower Systems, Inc. reserves the right to change information shown on website and download documents. Consult factory prior to ordering.

Size | Model No. | Electrical

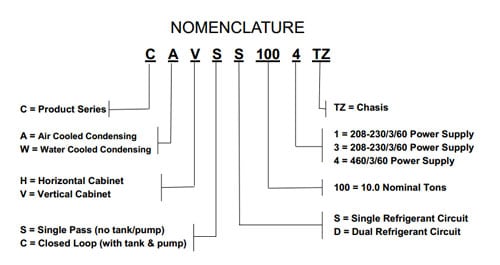

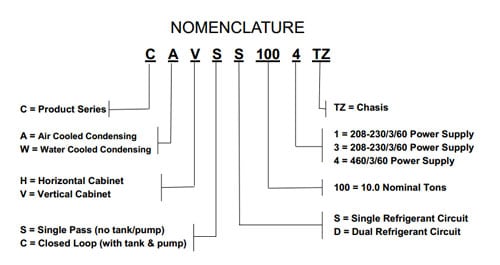

2.0 Ton – CAVCS0201TZ – 208-230/1/60

3.0 Ton – CAVCS0301TZ – 208-230/1/60

3.0 Ton – CAVCS0303TZ – 208-230/3/60

3.0 Ton – CAVCS0304TZ – 460/3/60

4.0 Ton – CAVCS0401TZ – 208-230/1/60

4.0 Ton – CAVCS0403TZ – 208-230/3/60

4.0 Ton – CAVCS0404TZ – 460/3/60

5.0 Ton – CAVCS0501TZ – 208-230/1/60

5.0 Ton – CAVCS0503TZ – 208-230/3/60

5.0 Ton – CAVCS0504TZ – 460/3/60

6.5 Ton – CAVCS0653TZ – 208-230/3/60

6.5 Ton – CAVCS0654TZ – 460/3/60

7.5 Ton – CAVCS0753TZ – 208-230/3/60

7.5 Ton – CAVCS0754TZ – 460/3/60

10 Ton – CAVCS1003TZ – 208-230/3/60

10 Ton – CAVCS1004TZ – 460/3/60

12.5 Ton – 2 Stage – CAVCS1253TZ – 208-230/3/60

12.5 Ton – 2 Stage – CAVCS1254TZ – 460/3/60

15 Ton – 2 Stage – CAVCS1503TZ – 208-230/3/60

15 Ton – 2 Stage – CAVCS1504TZ – 460/3/60

20 Ton – 2 Stage – CAVCS2003TZ – 208-230/3/60

20 Ton – 2 Stage – CAVCS2004TZ – 460/3/60

Size | Model No. | Electrical

1.5 Ton – CAVSS0151-TZ – 208-230/1/60

2.0 Ton – CAVSS0201-TZ – 208-230/1/60

3.0 Ton – CAVSS0301-TZ – 208-230/1/60

3.0 Ton – CAVSS0303-TZ – 208-230/3/60

3.0 Ton – CAVSS0304-TZ – 460/3/60

4.0 Ton – CAVSS0401-TZ – 208-230/1/60

4.0 Ton – CAVSS0403-TZ – 208-230/3/60

4.0 Ton – CAVSS0404-TZ – 460/3/60

5.0 Ton – CAVSS0501-TZ – 208-230/1/60

5.0 Ton – CAVSS0503-TZ – 208-230/3/60

5.0 Ton – CAVSS0504-TZ – 460/3/60

6.5 Ton – CAVSS0653-TZ – 208-230/3/60

6.5 Ton – CAVSS0654-TZ – 460/3/60

7.5 Ton – CAVSS0753-TZ – 208-230/3/60

7.5 Ton – CAVSS0754-TZ – 460/3/60

American Chillers will provide a replacement part for any covered defective part as per the above conditions. Customers are responsible for shipping charges after the first 30 day period. Replacement parts may be new or reconditioned, at the discretion of American Chillers. All warranty claims must be processed through American Chillers. The replacement part will be warranted for the remainder of the original part warranty or a minimum of 90 days.

Compressors must have the connections securely plugged or pinched and soldered shut to prevent any oil, leakage during shipment. Failure to follow this procedure will void the warranty on the compressor. A $50.00 handling fee will be assessed for compressor warranty returns.

All warranty claims must be processed through American and all parts returned for credit must have a Return Material Authorization (RMA) number. To make a warranty claim, contact American Chillers between the hours of 8:00 a.m. – 4:30 p.m. (Eastern time), Monday – Friday. American Chillers will issue an RMA number. The RMA number must be clearly marked on the outside packaging or the package will be refused. Return parts must be packaged securely to avoid shipping damage. Parts damaged during shipment will not be credited.

No parts will be shipped without payment. Parts must be paid for prior to shipment. American Chillers will accept VISA and MasterCard for your convenience. Your credit card will not be billed until the part(s) are shipped. Credit will be issued for the cost of the part, less any applicable freight and handling charges, after the defective part(s) are returned, freight prepaid, if the part failed due to a defect of material or workmanship. Return parts must be received within 30 days of making the claim. No credit or refunds will be given after 30 days.

Warranty policies may vary by customer, equipment and/or job. Refer to your sales documents for warranty details specific to your purchase.

AMERICAN CHILLERS © 2024 – DEVELOPED BY SUWEBCR