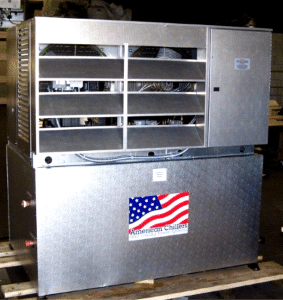

Chillers for Varian Linear Accelerators

We understand the run cycles of Varian Linear Accelerators and our chillers are custom engineered to meet the large cooling swings required. By providing a custom engineered chiller, we can not only provide more efficient cooling, but minimize or eliminate down time. We also offer back up options from Automatic City Water Bypass Panels to partially and fully redundant chiller systems.

Cooling Challenge: Varian sizes their heat load requirement for testing mode – not for daily operational loads. The heat load for stand-by mode is approximately 10% of the load for testing. The load for scanning is approximately 50% of the testing load. The use of an off-the-shelf chiller will result in short-cycling, insufficient cooling and premature failure of the chilling system.

Choose your chiller wisely! Improper chiller selection will lead to premature failure and constant maintenance leaving your oncology equipment in-operational.

Contact US For Price Lists, Technical Data and a Quotation.

*List does not include every model. If your Linear Accelerator/Oncology Equipment isn’t shown, contact us with the chilled water specification and we will provide our offering.