What Contractors & Engineers Must Know About A2L Chiller Requirements

A Clear Guide to the 2026 Chiller A2L Refrigerant Requirements

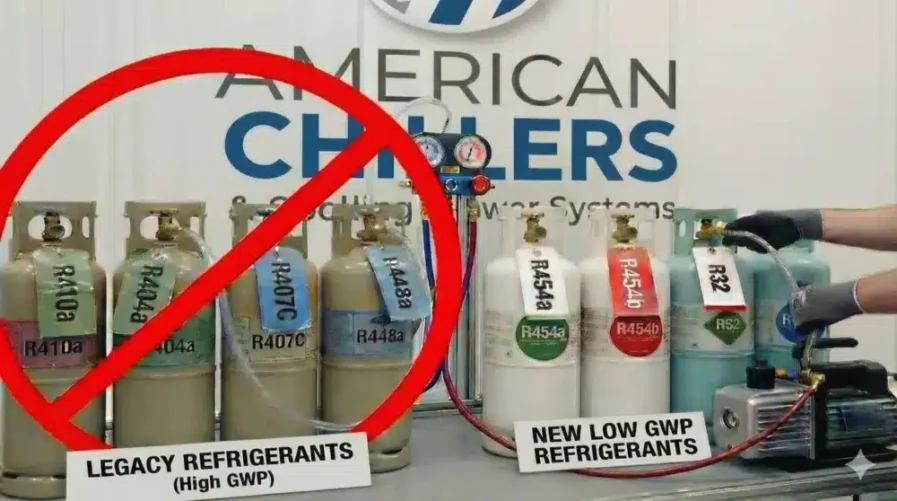

The HVAC and refrigeration industry is gearing up for one of the biggest regulatory changes in recent history. Beginning January 1, 2026, federal regulations will require a shift away from traditional high-GWP (Global Warming Potential) refrigerants like R-410A, R-404A, and R-407C. In their place, newer A2L refrigerants—classified as mildly flammable and significantly more environmentally friendly—will become the new standard.

This transition represents a major step toward sustainability, and it’s important for chiller manufacturers, contractors, and end-users to understand what’s coming and how it will affect system design, installation, and operation.

Why Is This Refrigerant Change Happening?

The refrigerant shift is driven by the American Innovation and Manufacturing (AIM) Act, which mandates an 85% phasedown of HFCs by 2036. Legacy refrigerants such as R-410A carry a high environmental impact, contributing heavily to greenhouse gas emissions.

A2L refrigerants—including blends like R-32, R-454A, and R-454B—deliver similar or even improved performance while offering a dramatically lower GWP. These requirements also align with global regulatory trends already in place across Europe and Asia, making the transition part of a worldwide effort to reduce climate impact.

What Exactly Are A2L Refrigerants?

A2L refrigerants fall into a safety classification that identifies them as:

- Lower flammability (much less flammable than A3 refrigerants like propane)

- Lower GWP—typically 70–80% lower than traditional HFCs

- Efficient and reliable for modern cooling applications

While they offer major environmental benefits, they also require updated safety standards, installation procedures, and building code compliance to account for their mild flammability.

Key Regulatory Changes Coming in 2026

Here’s what will take effect beginning in 2026 for most systems:

1. Process Chiller Manufacturing Prohibitions

Manufacturers will no longer be allowed to produce new equipment using high-GWP HFCs such as R-410A, R-404A, or R-407C.

2. Chiller Installation Restrictions

Contractors may be prohibited from installing any newly manufactured systems that still contain phased-out refrigerants.

Existing equipment can remain in service.

3. Updated Safety Standards

Agencies are adopting updated versions of:

- ASHRAE 15

- ASHRAE 34

- UL 60335-2-40

These standards outline requirements related to ventilation, leak detection, allowable charge sizes, and equipment construction to ensure safe use of mildly flammable refrigerants.

4. Building Code Updates as they pertain to American Industrial Process Chillers

States across the U.S. are currently revising their building codes to allow A2L installations. Widespread adoption is expected by late 2025.

What This Means for American Chillers

All new systems that would have previously used R-410A or R-407C are now being built with compliant refrigerants—such as R-454B, R-454A, or R-32—ensuring every chiller we manufacture meets the 2026 requirements.

Chillers with a portion indoors (splits and water-cooled unit)

What This Means for Customers of American Chillers

For customers purchasing new industrial chillers from us in 2026, the refrigerant transition is taken care of—the chiller will arrive fully compliant with the new standards.

The main area where customers may notice a change is in new chiller installation requirements. Because A2Ls are mildly flammable, safety codes now require that any portion of a chiller located indoors must either:

- Be installed in a space large enough to safely disperse a potential leak, or

- Include proper mechanical ventilation.

- Be installed outdoors

These requirements are designed to ensure safe operation and reduce risk in the unlikely event of refrigerant leakage. Our indoor units (split and water-cooled chillers) include a leak detection sensor as a safety feature to help trigger ventilation (if applicable) and turn off the chiller.

For decades, American Chillers has assisted thousands of clients across the U.S. and Canada, providing technical guidance on industrial process chiller solutions. American Chillers engineering and support teams assist from early site planning through long-term system operation. While contractors remain responsible for meeting local codes and securing approvals, American Chillers is a reliable resource for helping to interpret A2L requirements and supporting safe system integration.

Contact American Chillers today for your next industrial process chiller project.