ABOUT GLYCOL IN CHILLERS

An industrial process chiller will run without glycol as long as the fluid, evaporator and ambient temperatures stay above freezing. Glycol or other inhibitors are recommended for most process cooling applications even if the fluid and ambient air temperatures don’t reach temperatures near freezing.

What type of glycol is best?

American Chillers recommends Inhibited Propylene Glycol which works as an anti-freeze, but also includes rust inhibitors and other additives that keeps your pump seals lubricated and fluids and chilled water system running in optimal condition. Other glycols may be acceptable. NEVER USE AUTOMOTIVE OR RV ANIT-FREEZE IN CHILLERS. Be cautious if using glycol in cooling towers. Glycol will reduce capacity. Questions about what glycol concentration and/or type to purchase? Contact and American Chillers sales engineer for assistance.

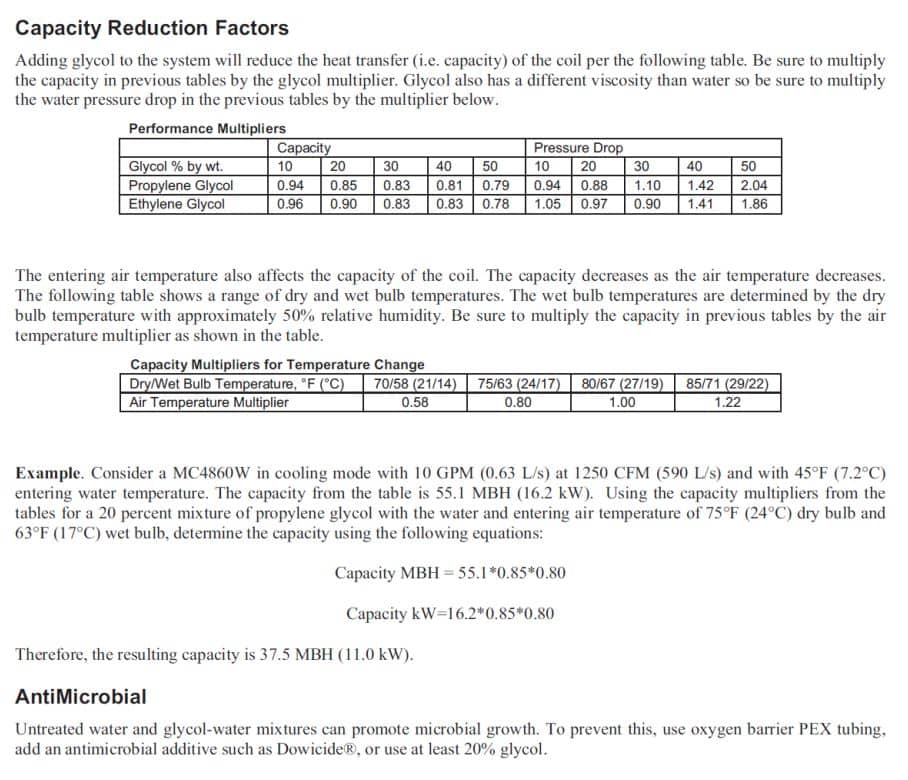

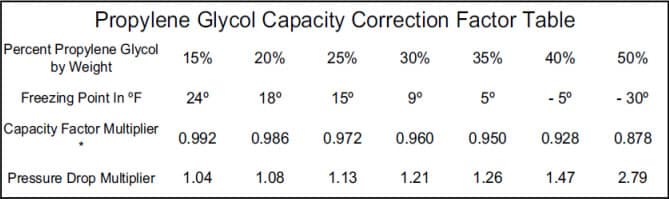

Glycol Correction Factors

All Heat exchangers experience a capacity loss when the fluid is a higher specific gravity than water. Glycols are heavy, syrup like fluids at full concentration, and become thinner when mixed with water. However, the mixed solution of water-glycol will be thicker, heavier, than the water alone was. Thus, to achieve the same heat exchange inside the heat exchanger , requires more surface area or a larger heat exchanger. American Chillers heat exchangers are engineered for full rated capacity with the use of 30% glycol solutions. Our heat exchangers start out with 30% more surface area capacity than the heat exchangers used by other manufacturers so you still have full capacity with 30% water-glycol solutions. If you are using glycol concentrations above 30%, consult factory prior to purchasing your chiller for chiller selection assistance.

Propylene Glycol

| Leaving Temperature Degrees F | 30% | 40% | 50% | |||

| Capacity Factor | Pressure Drop Factor | Capacity Factor | Pressure Drop Factor | Capacity Factor | Pressure Drop Factor | |

| 20 | – | – | 0,8 | 1,74 | 0,74 | 2,07 |

| 30 | 0,92 | 1,39 | 0,87 | 1,63 | 0,82 | 1,94 |

| 40 | 0,93 | 1,36 | 0,89 | 1,55 | 0,85 | 1,83 |

| 45 | 0,94 | 1,35 | 0,9 | 1,53 | 0,87 | 1,81 |

| 50 | 0,94 | 1,33 | 0,91 | 1,51 | 0,88 | 1,75 |

| 55 | 0,95 | 1,31 | 0,92 | 1,5 | 0,89 | 1,73 |

| 60 | 0,95 | 1,31 | 0,92 | 1,47 | 0,9 | 1,68 |

| 70 | 0,96 | 1,27 | 0,93 | 1,43 | 0,91 | 1,63 |

| Minimum leaving fluid temperature | 25°F | 10°F | -10°F | |||

| Minimum ambient | 10°F | -4°F | -20°F | |||

Glycol Capacities and Correction Tables

* At standard ARI 590 conditions: 54°F entering fluid temperature, 44°F leaving fluid temperature, 95°F ambient temperature, 0.0005 fouling

American Chillers engineers recommend propylene based glycols for most applications because of their non-hazardous nature. USP rated propylene glycol may even be food safe and is recommended for breweries, wineries and food processing cooling applications.

When using glycol, it is important to be aware of the effects on heat exchangers and pumps.

A 40% solution of propylene glycol will reduce the chiller heat exchanger’s ability to chill by at least 7.2%. We know from experience, that some heat exchangers chilling abilities is reduced by 20%. This means the chiller with a 10-ton capacity for chilling water will have a capacity between 8 tons and 9.3 tons with 40% PG. Most American Chillers have heat exchangers that are oversized to handle 30% PG without any loss of capacity. We can easily provide a chiller heat exchanger for even 50% PG at the customer request at time of order. Some glycol in the system will lubricate pump seals, but too much glycol in a system especially in cold fluid applications or if starting cold during winter weather can damage pumps. Make sure that you consult with a glycol expert like our engineers at American Chillers for guidance into the optimal glycol percentages for your system.