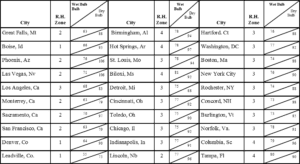

In order to size a cooling tower, you will need to know your process flow (gallons per minute) and supply and return fluid temperatures. You will also need to know the wet bulb and ambient temperatures for the area where you are located. Use the charts below to size your cooling tower. Note – the model numbers do not reference air-conditioning tons.

FRP Cooling Tower Sizing Chart

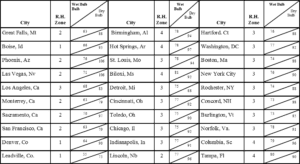

To determine the wet bulb for your city, refer to the chart below or contact American Chillers

Additional Considerations

Why Do FRP Cooling Towers Work Better in Dry Climates?

FRP Cooling Towers work better in dry climates than in humid climates simply because there is more water evaporation that takes place in a dry location or on a dry day VS a humid day.

What’s a Quick Method for Determining Cooling Tower Size?

You can look at the charts above or if you are located east of the Mississippi River, and know the chiller size, simply double the chiller size then go up one size. For example, if you need a 5-ton chiller, you might choose an ACTS-15 cooling tower. The map at the right illustrates dry climates and low humidity areas as 1 and 2 against the humid areas of 3 and 4.

Areas 3 and 4 are very humid and FRP Cooling Towers are about half as efficient here as in areas 1 and 2.

When is a Chiller Sizing and FRP Cooling Tower Sizing equal?

In areas 1 and 2 a cooling tower will probably reject as many BTU’s per ton of rating as a chiller. If a machine needs a 10-ton chiller it will probably perform equally with a 10-ton tower.

The same machine in areas 3 and 4 will typically require a tower twice as big as the chiller, due to the factor we call wet bulb temperature.

The wet bulb temperature is defined as that temperature that the ambient temperature (dry bulb temperature) and the relative humidity working together make happen. It is not theoretical; it is very real. Hot is not a bad thing for evaporation. In fact, evaporation is very rapid in the desert (Las Vegas @ 71° W.B.) at 100°. Humidity works against the heat, however, and retards the evaporation rate. An average humidity of 85% will reduce the rate by at least half.

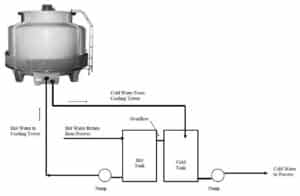

Evaporation Cools the Water

Cooling towers are engineered to evaporate moving water as it passes over PVC or other material and air is blown through it. The more evaporation that takes place, the better the cooling. The simple explanation is that when water changes state from a liquid to a gas it consumes BTUs, or heat. Evaporation of a pound of water will consume nearly 1,000 Btu’s. That loss of heat will change the temperature of the water left behind, slightly.

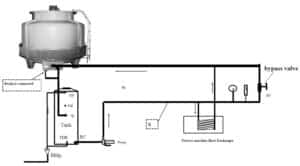

Chiller vs. tower

By design, cooling towers are high flow rate devices. Nominal flow rates of 2.5 to 3.0 gallons/ ton/minute are normal. The 10-ton chiller will also circulate approximately 2.5 gallons per minute/ton, and because it is mechanically cooled with refrigeration, the nominal cooling is 8 to 10 degrees each time a gallon of water passes through the heat exchanger.

Ideally, a cooling tower would match that, and it will in areas 1 and 2 most of the time. Un fortunately, in areas 3 and 4, the wet bulb temperatures are much higher and in the peak of summer when it is hot and humid at the same time, the tower may only cool that gallon of water 2- or 3-degrees F each pass through the tower. Chillers, then, are a huge advantage at these times.

Install bigger towers to compensate (more on chiller VS tower sizing)!

The norm in areas 3 and 4 is: Tower Size = 2 x Chiller Size. If an application calls for a 10-ton chiller, a 20-ton cooling tower is recommended. The net result is that by moving twice the water (flow rate) the reduced temperature drop can be compensated for by cooling the water twice, instead of once.

Point of no return

When (not if) the wet bulb temperature is higher (it is hot and humid!) the ability of the tower regardless of tower size is less. I t doesn’t matter if you install a 100-ton tower and circulate 300 gallons per minute, if the wet bulb temperature is 77°, the best you can get is probably 3° to 5° above that, or 80° to 82°. The table below lists some major U.S. cities with the design dry bulb and wet bulb temperature ratings as listed by the American Refrigeration Institute. Add a few degrees to the wet bulb and you will have the coolest water temperature attainable in the worst summer months. Put another way, the wet bulb temperature is that worst (hottest)

temperature attainable; and 97% of the time it will be cooler.

The key is to be able to cope with those times when wet bulb is the highest or to consider using a chiller instead of a cooling tower if your process doesn’t allow for variation (critical cooling processes).

Maintenance of towers

Fact 1: Maintenance is crucial to the efficient operation of Cooling Towers.

Fact 2: The better cooling towers work (evaporate water) the dirtier towers become and the more maintenance they require.

Fact 3: From the first minute a new tower goes online, it starts to lose efficiency and the ability to cool. This is another reason to oversize them to maintain cooling capacity as they age.

Summary

You can see from the table that if the humidity is low (Las Vegas or Phoenix) and the dry bulb (ambient) temperature is high (100°F +) the cooling ability of a tower is very, very good. That 71° wet bulb in Las Vegas means the tower will yield 75° or cooler water 97% of the time. Even when it is 106°F in the shade!

We personally measured a roof top temperature of 157° at 2:30 p.m. once! And don’t tell me “Yea, but it is a dry heat!” It was bloody hot! Yet, the tower was producing 65° water!

On the other hand, that same tower had to be replaced every three years because the buildup of minerals from poor water quality.

Look at Tampa @ 80° and Pensacola @ 81°, with a dry bulb of 90° and 91°, respectively. Not only is the humidity so thick you can cut it with a knife, but it is also hot. And that is not a dry heat! No wonder that a tower can only produce 95° water in the peak of summer. The tap ( ground ) water is 85°.

When does a cooling tower becomes a water heater?

Assuming, you have 75° water coming out of the process, and you send it to a cooling tower because you want 65°, what temperature will you get back? Answer: In the case of the Tampa tower above, 95°degrees!

This dispels the assumption that a refrigeration coil in the tank is a good “booster” or supplement for the tower. A helper chiller can be used, but not by putting a coil in the tank. It would take a 12.5-ton chiller to “help” a 10-ton tower by 10° that way! It all gets down to wet bulb and flow rates and Btu’s and pounds per minute and horsepower.

If you have questions on sizing your cooling tower or a cooling problem for which you

need assistance, feel free to contact us. We will be happy to assist you!