DRY CLEANING CHILLERS

Exclusively for Union, Realstar, Columbia, Multimatic, Firbimatic and more..

More than 30-years

American Chillers

3 to 20 Nominal tons.

-

- Package: tank, pump refrigeration all in one unit

- Modular: outdoor chiller with indoor tank and pump

- Split: indoor chiller with outdoor condensing unit (connects with refrigeration line set)

For sizes over 20 tons, please contact our sales department

See also Cooling Towers For Dry Cleaning

Standard Features

- Heavy duty welded, tubular steel frame with high gloss powder coat finish and laminated polyethylene cabinet

- U.L. Listed, and EPA Compliant, eco-friendly R410a refrigeration condensing unit

- Single refrigeration circuit with Copeland scroll compressor with crankcase heater

- Air cooled, high ambient, vertical discharge, condensers for 100°F ambient with fan cycle low ambient control

- Weather proof electrical panel with single point power connection and 24 vac control circuit

- Remote control panel for indoor installation provides lighted on/off switches and digital thermostat

- High performance stainless steel evaporator UL listed, and insulated with closed cell insulation

- Auto reset low pressure safety; manual reset high pressure safety

- Externally equalized thermal expansion valve, liquid line filter drier, and sight glass

- Low water flow compressor interlock safety locks out compressors in low flow condition

- Non-ferrous water lines with FPT connections insulated with 1/2” closed cell insulation

- High density, polyethylene reservoir insulated with 1/2” closed cell insulation

- High head centrifugal process pump rated at approximately 40 psi at 2.5 GPM/ton

- Wye strainer included (shipped loose)

- Systems leak checked, pressure tested, run tested under load and shipped operation ready

- Warranty: one (1) year limited parts, five (5) years limited compressor warranty

Available Options

- Receivers for 90% refrigerant storage (heated and insulated for temperatures below 30°F ambient)

- Condenser coil coating for corrosion protection in coastal areas

- Fan speed control to maintain steady head pressure in cold ambient

- Voltage and phase monitor in 2 through 7.5 ton

- Cabinet mounted glycerin filled fluid supply pressure gauge

- Cabinet mounted, glycerin filled refrigeration pressure gauges

- Cabinet mounted, analog fluid inlet and outlet gauges

- Inhibited propylene glycol concentrate or 65% / 35% premix in 55 gallon drums or 5 gallon carboys

- Castors for portability

- Factory authorized technician for startup and training

- Factory authorized contractor for installation

Modular Chiller Specification Sheets

Dry Cleaning PDF Spec Sheet Downloads

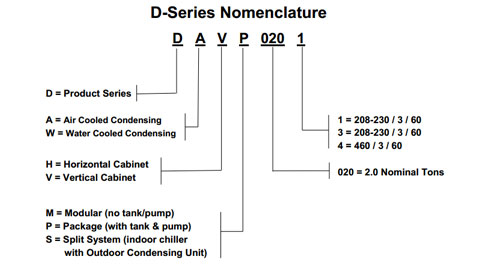

Size | Model No. | Electrical

3.0 TONS | DAVM0301 | 208-230/1/60

3.0 TONS | DAVM0303 | 208-230/3/60

3.0 TONS | DAVM0304 | 460/3/60

4.0 TONS | DAVM0401 | 208-230/1/60

4.0 TONS | DAVM0403 | 208-230/3/60

4.0 TONS | DAVM0404 | 460/3/60

5.0 TONS | DAVM0501 | 208-230/1/60

5.0 TONS | DAVM0503 | 208-230/3/60

5.0 TONS | DAVM0504 | 460/3/60

6.5 TONS | DAVM0653 | 208-230/3/60

6.5 TONS | DAVM0654 | 460/3/60

7.5 TONS | DAVM0753 | 208-230/3/60

7.5 TONS | DAVM0754 | 460/3/60

10.0 TONS | DAVM1003 | 208-230/3/60

10.0 TONS | DAVM1004 | 460/3/60

12.5 TONS | DAVM1253 | 208-230/3/60

12.5 TONS | DAVM1254 | 460/3/60

15.0 TONS | DAVM1503 | 208-230/3/60

15.0 TONS | DAVM1504 | 460/3/60

20.0 TONS | DAVM2003 | 208-230/3/60

20.0 TONS | DAVM2004 | 460/3/60

Packaged Chiller Specification Sheets

Dry Cleaning PDF Spec Sheet Downloads

Size | Model No. | Electrical

2.0 TONS | DAVP0201 | 208-230/1/60

3.0 TONS | DAVP0301 | 208-230/1/60

3.0 TONS | DAVP0304 | 460/3/60

4.0 TONS | DAVP0401 | 208-230/1/60

4.0 TONS | DAVP0403 | 208-230/3/60

4.0 TONS | DAVP0404 | 460/3/60

5.0 TONS | DAVP0501 | 208-230/1/60

5.0 TONS | DAVP0503 | 208-230/3/60

5.0 TONS | DAVP0504 | 460/3/60

6.5 TONS | DAVP0653 | 208-230/3/60

6.5 TONS | DAVP0654 | 460/3/60

7.5 TONS | DAVP0753 | 208-230/3/60

7.5 TONS | DAVP0754 | 460/3/60

10.0 TONS | DAVP1003 | 208-230/3/60

10.0 TONS | DAVP1004 | 460/3/60

12.5 TONS | DAVP1253 | 208-230/3/60

12.5 TONS | DAVP1254 | 460/3/60

15.0 TONS | DAVP1503 | 208-230/3/60

15.0 TONS | DAVP1504 | 460/3/60

20.0 TONS | DAVP2003 | 208-230/3/60

20.0 TONS | DAVP2004 | 460/3/60

Installation Examples

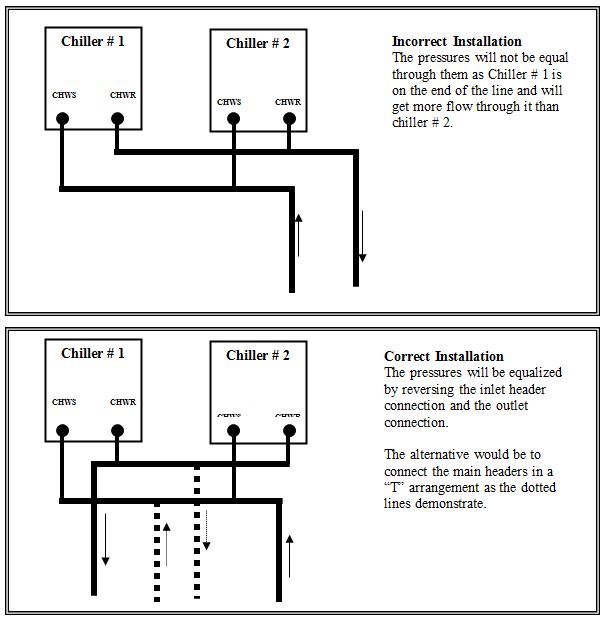

How to Pipe Chillers in Parallel

Two or more chillers may be installed in a parallel piping system to provide more capacity of a single chiller or redundancy and multi-staging of compressors. Normally the load on the chilled water system dictates the system capacity and the part load capacity of the process is the factor to determine the staging of the chillers on temperature. The thermostats can be set a few degrees apart. If one chiller cannot maintain the fluid temperature, the second chiller will stage on upon temperature rise and a third, etc.

The diagram below illustrates the concept of parallel piping of the chillers on a common header system. The main header must be sized for the total flow rate and good practices dictates a maximum flow rate of 7 Ft/sec.

When adding a chiller to an existing manifold system, also consider the ability of the pump to provide enough total flow and pressure to satisfy the process and the continuous flow through the chillers. Nominal flow rate for commercial equipment of 2.5 gpm / ton are normally a minimum with 70 to 100 ft. hd. (30 psi to 43 psi) capability. Contact American Chillers engineers for assistance.

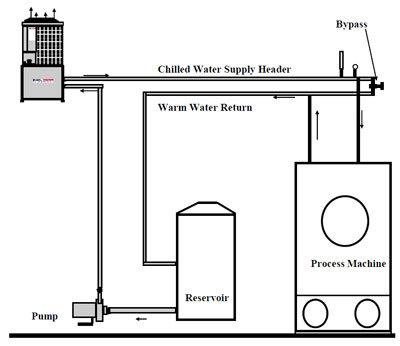

Dry Cleaning Chiller Installation

Installing A Bypass Loop

Purpose:

- To provide a continuously circulating water flow through the chiller coil, tank and piping system. This is necessary to maintain the reservoir at the cold temperature setting. The system should be balanced so that the flow through the bypass loop while maintaining sufficient flow to the process.

- To establish the minimum operating pressure of the cooling water supply to the process machine. This is a result of setting the continuous flow at maximum. This also establishes a high pressure supply to the process machine and a low pressure return to the chiller for good circulation through the process machine heat exchangers. The differential pressure between the supply and return should be a minimum of 20 psi.

- To allow the chiller refrigeration to cycle on and off freely, and independently of external demands for flow and temperature.

Where To Put The Bypass:

The bypass valve must be located at the end of the line, with the process machine connections between the bypass and the pump.

The illustration below shows a modular chiller system with the process (dry cleaning) machine correctly connected to the piping between the pump and the bypass.

The pressure to the process machine (s) will be the same every inch in the line between the bypass and the pump. Two machines can be connected and their supply pressure will be the same.

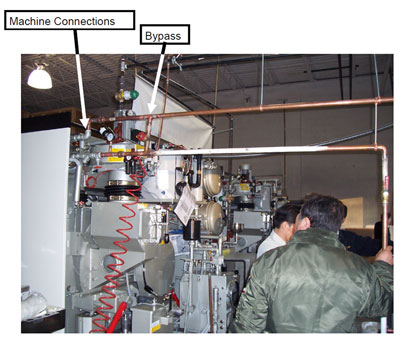

The picture shows the bypass before the process machine connections and the pressure will be lower to the machine when the bypass is open. The drop in pressure will increase as the bypass is opened and set for optimum flow to the chiller. The process machine heat exchangers very likely will starve for cooling as a result.

This photo clearly shows the wrong way to connect the bypass. The natural tendency of the operator when the process machine alarms due to lack of cold water is to close the bypass to force more pressure and flow to the process machine heat exchangers.

Starving the Chiller:

The process machine will get more pressure and flow as a result of closing the bypass – But what happens to the chiller?

The chiller will starve for flow causing the water temperature to be very cold coming out of the chiller but at a reduced flow that will cause the loop temperature to swing wildly between cold and hot! The purpose of the flowing loop has been defeated and the chiller can not maintain the reservoir and loop temperature at an even temperature. The temperature fluctuations of the water supply can be 30 to 40 degrees or more.

Bypass Line Size:

The piping connections on the chiller are the correct size for the supply and return header lines based on sound engineering principles of flow, pressure drops, and fluid velocity. Reducing the line size from the recommended causes higher velocities, higher pressure drops, reduced supply pressure to the process machine, and fluctuations in the supply temperature.

Glycol Charts & Information

ABOUT GLYCOL IN CHILLERS

A chiller will run without glycol as long as the fluid temperature in the system is above freezing. Glycol or other inhibitors are recommended for most process cooling applications even if the fluid temperature doesn’t reach temperatures near freezing.

What type of glycol is best?

American Chillers recommends Inhibited Propylene Glycol which works as an anti-freeze, but also includes rust inhibitors and other additives that keeps your pump seals lubricated and fluids and chilled water system running in optimal condition. Other glycols may be acceptable.

NEVER USE AUTOMOTIVE OR RV ANIT-FREEZE IN CHILLERS.

NEVER USE GLYCOL IN COOLING TOWERS.

Glycol will reduce chiller capacity.

Questions about what glycol concentration and/or type to purchase? Contact and American Chillers sales engineer for assistance.

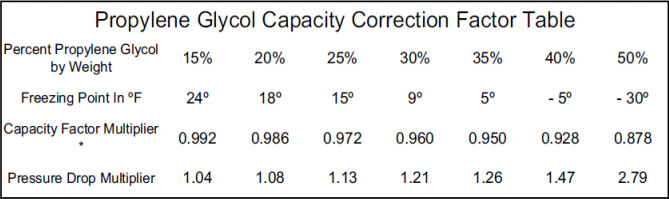

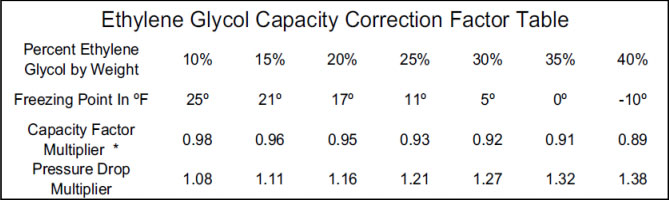

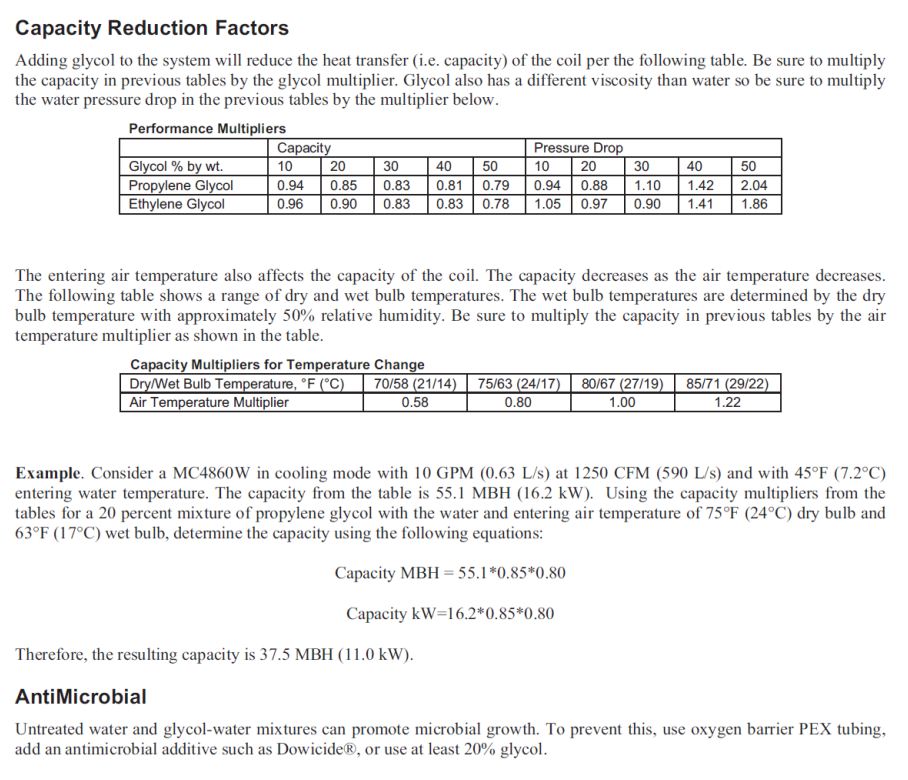

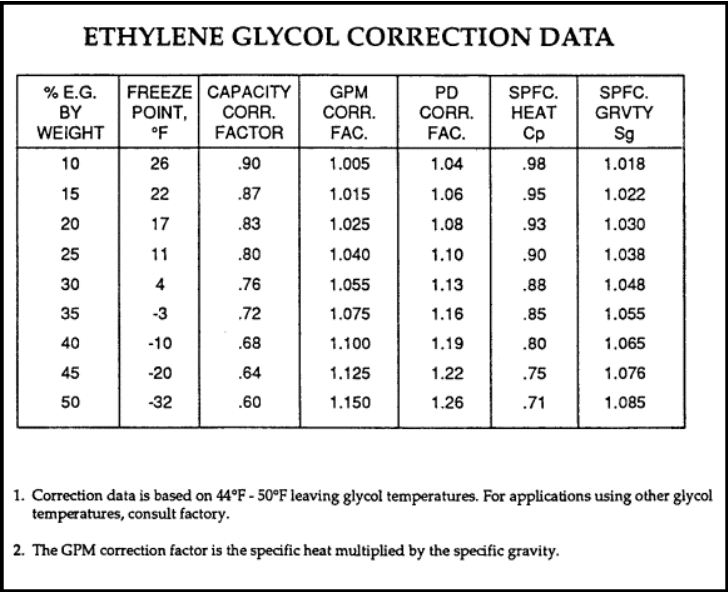

Glycol Correction Factors

All Heat exchangers experience a capacity loss when the fluid is a higher specific gravity than water. Glycols are heavy, syrup like fluids at full concentration, and become thinner when mixed with water. However, the mixed solution of water-glycol will be thicker, heavier, than the water alone was. Thus, to achieve the same heat exchange inside the heat exchanger , requires more surface area or a larger heat exchanger.

American Chillers heat exchangers are engineered for full rated capacity with the use of 30% glycol solutions. Our heat exchangers start out with 30% more surface area capacity than the heat exchangers used by other manufacturers so you still have full capacity with 30% water-glycol solutions. If you are using glycol concentrations above 30%, consult factory prior to purchasing your chiller for chiller selection assistance.

Propylene Glycol

| Leaving Temperature Degrees F | 30% | 40% | 50% | |||

| Capacity Factor |

Pressure Drop Factor |

Capacity Factor |

Pressure Drop Factor |

Capacity Factor |

Pressure Drop Factor |

|

| 20 | – | – | 0,8 | 1,74 | 0,74 | 2,07 |

| 30 | 0,92 | 1,39 | 0,87 | 1,63 | 0,82 | 1,94 |

| 40 | 0,93 | 1,36 | 0,89 | 1,55 | 0,85 | 1,83 |

| 45 | 0,94 | 1,35 | 0,9 | 1,53 | 0,87 | 1,81 |

| 50 | 0,94 | 1,33 | 0,91 | 1,51 | 0,88 | 1,75 |

| 55 | 0,95 | 1,31 | 0,92 | 1,5 | 0,89 | 1,73 |

| 60 | 0,95 | 1,31 | 0,92 | 1,47 | 0,9 | 1,68 |

| 70 | 0,96 | 1,27 | 0,93 | 1,43 | 0,91 | 1,63 |

| Minimum leaving fluid temperature | 25°F | 10°F | -10°F | |||

| Minimum ambient | 10°F | -4°F | -20°F | |||

Ethylene Glycol

| Leaving Temperature Degrees F | 30% | 40% | 50% | |||

| Capacity Factor |

Pressure Drop Factor |

Capacity Factor |

Pressure Drop Factor |

Capacity Factor |

Pressure Drop Factor |

|

| 20 | 0,92 | 1,39 | 0,89 | 1,61 | 0,86 | 1,86 |

| 30 | 0,96 | 1,34 | 0,93 | 1,53 | 0,9 | 1,78 |

| 40 | 0,96 | 1,33 | 0,94 | 1,52 | 0,92 | 1,74 |

| 45 | 0,96 | 1,33 | 0,94 | 1,51 | 0,93 | 1,72 |

| 50 | 0,96 | 1,31 | 0,95 | 1,49 | 0,93 | 1,69 |

| 55 | 0,96 | 1,31 | 0,95 | 1,47 | 0,94 | 1,67 |

| 60 | 0,97 | 1,31 | 0,96 | 1,47 | 0,94 | 1,65 |

| 70 | 0,97 | 1,27 | 0,96 | 1,49 | 0,95 | 1,62 |

| Minimum leaving fluid temperature | 20°F | 5°F | -15°F | |||

| Minimum ambients | 5°F | -9°F | -28°F | |||

Glycol Capacities and Correction Tables

* At standard ARI 590 conditions: 54°F entering fluid temperature, 44°F leaving fluid temperature, 95°F ambient temperature, 0.0005 fouling

The charts, above, illustrate the differences between propylene based and ethylene based glycol. Since we recommend propylene based glycols because of their non-hazardous nature, we must be aware of the effects on the standard refrigeration heat exchangers and pumps.

A 40% solution of propylene glycol will reduce the chiller heat exchanger’s ability to chill by at least 7.2%. We know from experience, that some heat exchangers chilling abilities is reduced by 20%. This means the chiller with a 10 ton capacity for chilling water will have a capacity between 8 tons and 9.3 tons with 40% PG.

Most American Chillers have heat exchangers large enough to handle 30% PG without loss of capacity due to our “value-added” engineering practices. We can easily provide a chiller heat exchanger for even 50% PG at the customer request at time of order.

Free Cooling / Energy Savings

Installation & Maintenance

Warranty

What Is Covered:

1. All parts are guaranteed to be free of defects in material and workmanship for 12 months from date of original purchase.

2. Scroll compressors are guaranteed to be free of defects in material and workmanship for 60 months from date of purchase.

3. Labor: during the first 30 days after startup, American Chillers will reimburse the owner for any reasonable labor charges incurred for the replacement of a warranted part, according to the rate schedule. A time allowance of 30 minutes, for one technician is allowed for the diagnosing of a malfunction. Consult customer service for the labor rate schedule .

4. During the first 30 days after startup, American Chillers will pay for regular, ground shipping of any covered part shipped to

the customer. Express shipping and air freight charges are the responsibility of the customer. After 30 days, the customer is responsible for shipping defective parts back for credit and for the shipping charges from American Chillers to the customer.

What is not covered:

1. shipping costs after the initial 30 days. Express shipping charges over regular ground charges are not covered.

2. Labor charges of a helper during repair; truck, mileage, and transportation charges; time over 30 minutes to diagnose a problem’s cause.

3. Labor rates in excess of pre-negotiated wholesale rates, usually no more than 70% of regular retail. American Chillers does not pay retail labor rates.

4. Loss of business or added expense for cranes, lifts, permits, or contractor services arising from the repair or replacement of a failed part.

5. Failures caused by external factors beyond the control of this manufacturer and the component manufacturer.

6. Supplies used to effect the repairs such as solder, nitrogen gas, dyes, bubble soap, and leak detector.

7. Part or component failure must be a result of manufacturing defect or normal wear and tear. Parts that fail due to causes external to the chiller, such as improper installation, electrical supply problems, leaking or broken pipes and tube erosion from excessive fluid velocity, freezing or poor water quality, failure to maintain clean filters, contractor or owner negligence, etc., are not covered by this warranty. American Chillers will not reimburse the customer for locally purchased parts through another vendor without prior authorization. A replacement part, however, will be provided upon return of the defective part, only.

8. Electrical parts sent as replacement may not be returned for credit.

9. Glycol, replacement glycol, the labor to add glycol to the chiller and chiller damage resulting from improper freeze protection are not covered by the chiller warranty.

Policy Regarding Replacement Parts:

American Chillers will provide a replacement part for any covered defective part as per the above conditions. Customers are responsible for shipping charges after the first 30 day period. Replacement parts may be new or reconditioned, at the discretion of American Chillers. All warranty claims must be processed through American Chillers. The replacement part will be warranted for the remainder of the original part warranty or a minimum of 90 days.

Compressors:

Compressors must have the connections securely plugged or pinched and soldered shut to prevent any oil, leakage during shipment. Failure to follow this procedure will void the warranty on the compressor. A $50.00 handling fee will be assessed for compressor warranty returns.

To Make A Warranty Claim

All warranty claims must be processed through American and all parts returned for credit must have a Return Material Authorization (RMA) number. To make a warranty claim, contact American Chillers between the hours of 8:00 a.m. – 4:30 p.m. (Eastern time), Monday – Friday. American Chillers will issue an RMA number. The RMA number must be clearly marked on the outside packaging or the package will be refused. Return parts must be packaged securely to avoid shipping damage. Parts damaged during shipment will not be credited.

Payment

No parts will be shipped without payment. Parts must be paid for prior to shipment. American Chillers will accept VISA and MasterCard for your convenience. Your credit card will not be billed until the part(s) are shipped. Credit will be issued for the cost of the part, less any applicable freight and handling charges, after the defective part(s) are returned, freight prepaid, if the part failed due to a defect of material or workmanship. Return parts must be received within 30 days of making the claim. No credit or refunds will be given after 30 days.

Warranty policies may vary by customer, equipment and/or job. Refer to your sales documents for warranty details specific to your purchase.

Maybe you might be interested

What is the Best Way to Cool Your Dry Cleaning Facility?

I just returned from the Clean Show in New Orleans and read the June 2019 American Dry Cleaner Magazine that featured an article about giving employees better working conditions including keeping them cool. So what is the best way to cool your dry cleaning facility? Spot cooling is often the best and most cost effective […]

Long time customer Bob Ferber picking up his 7.5 ton American Chiller

Bob Ferber recently paid a visit to American Chillers to pick up a 7.5 ton horizontal chiller for a rooftop installation at a dry cleaning plant in New Jersey. Bob has been a loyal American Chillers customer since the 1980’s. Bob announced that he will be retiring and needed to see our new South Carolina […]